Trusted By Industry Leaders

.jpg?width=628&height=150&name=MonaghanMushroomsGroup%20(1).jpg)

.jpg?width=628&height=150&name=MonaghanMushroomsGroup%20(1).jpg)

FlowForma transforms how FMCG manufacturers, distributors, and retailers manage critical operational processes across the value chain, from product development and supplier onboarding to trade promotions, quality control, logistics, and compliance.

Its AI-powered platform accelerates workflows, improves data accuracy, and provides end-to-end visibility across departments and partners. By reducing manual effort and process delays, FMCG organizations can move faster, respond to market demand, and maintain consistent operational excellence.

The platform integrates seamlessly with ERP, supply chain, quality, and finance systems, scaling across business units and geographies while ensuring secure, auditable, and compliant processes.

Bringing new suppliers, co-packers, distributors, and promotional partners into your ecosystem is complex, manual, and error-prone. FlowForma’s AI-driven automation streamlines onboarding workflows, accelerates approvals, ensures data accuracy, and strengthens supplier compliance across regions and categories.

Managing price advice, trade promotions, discounts, and retailer rebate approvals involves multiple departments and frequent adjustments. Automated workflows with intelligent agents standardize data capture, accelerate approval cycles, reduce pricing errors, and ensure consistent execution across markets — improving promotional ROI.

From new product introduction (NPI) to formulation changes, packaging updates and regulatory submissions, FMCG product processes involve extensive documentation and cross-functional approvals. FlowForma simplifies product change requests and artwork iteration workflows with full traceability and stakeholder collaboration — ensuring fast time-to-shelf while maintaining quality and compliance.

Manual purchase order creation, batching, and approval processes often lead to stock imbalances and operational delays. Automated purchase order workflows, integrated with ERP and inventory systems, reduce manual errors, provide real-time visibility into orders, and improve inventory accuracy across warehouses and field locations.

Maintaining quality standards across production, storage, and distribution — especially for perishable goods — demands rigorous checks and records. FlowForma automates quality inspection workflows, batch release approvals, cold chain check-ins, and non-conformance reporting, helping teams proactively prevent issues and ensure regulatory readiness.

FMCG operations face complex labeling, safety, environmental and traceability regulations across markets. FlowForma’s platform embeds audit trails, automates compliance checks and documentation workflows, and provides visibility into process status. This reduces risk of fines, improves recall readiness, and makes compliance reporting faster and more reliable.

From supplier onboarding and product approvals to trade promotions and purchase orders, FlowForma automates critical FMCG workflows end-to-end, removing bottlenecks and freeing teams to focus on value-adding activities.

Track, audit, and enforce regulatory, quality, and internal controls across every process. Maintain full traceability for products, suppliers, and documentation while reducing risk and ensuring audit readiness.

AI agents automate data extraction, validation, exception handling, and risk flagging so processes run faster, smarter, and with greater accuracy across supply chain, quality, and commercial operations.

Connect seamlessly with ERP, supply chain, quality management, finance, and CRM systems to ensure consistent, accurate data across all platforms and business units.

Connect seamlessly with ERP, supply chain, quality management, finance, and CRM systems to ensure consistent, accurate data across all platforms and business units.

Gain live visibility into workflows, workloads, and operational performance. Make faster, data-driven decisions with actionable dashboards and detailed reporting.

"It’s essentially easier to map out a workflow in as simple a format as possible. FlowForma Process Automation is a lot more realistic and I like the way the knowledge around running it is transferred over to us.”

Systems Manager

‘‘The no code setup means the process owners are heavily involved; they can understand what is happening without requiring any knowledge of systems or coding language. It motivates people to learn how to maintain their own processes and extend them beyond their own sites.”

Global Procurement Manager, Nipro Europe Group

"Don’t let the initial investment be a blocker to transformation, once you digitalize 3 noteworthy processes with FlowForma Process Automation, you’ve already got your ROI."

Transformation Consultant

Global Food Producer takes critical workflows to the cloud

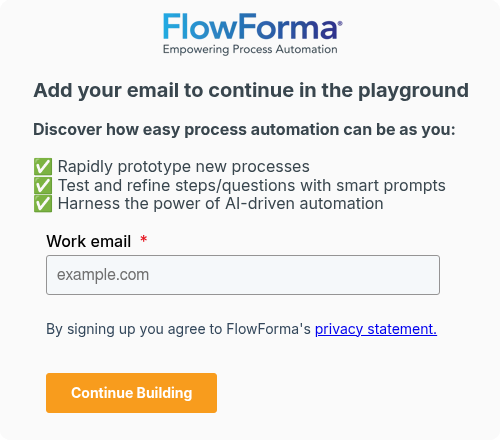

Experience the future of AI-powered process automation

The 2026 buyers guide to digital process automation software

Complete guide to agentic process automation

How process automation can support compliance

FlowForma is an AI-driven process automation platform that digitizes and automates end-to-end workflows. For FMCG organizations, it accelerates supplier onboarding, product approvals, trade promotions, purchase orders, quality inspections, and compliance processes, reducing manual effort, improving accuracy, and increasing operational agility.

FlowForma is a SharePoint-native application, which means it runs on top of Microsoft SharePoint Online.

It leverages SharePoint as the underlying document and data repository, and uses SharePoint lists and libraries to store workflow data, forms, and audit history.

FlowForma can automate a wide range of processes including supplier and distributor onboarding, new product introduction (NPI), artwork approvals, trade promotion and pricing approvals, purchase orders, inventory workflows, quality inspections, non-conformance reporting, recalls, compliance audits, and warehouse incident reporting.

FlowForma seamlessly connects with ERP, CRM, supply chain, quality management, finance, and other core systems, ensuring that data flows consistently across platforms. This eliminates duplication, reduces errors, and provides real-time visibility into operational workflows.

FlowForma embeds audit trails, validation rules, and automated checks within every workflow. It tracks all approvals, documents, and changes, helping FMCG companies stay compliant with regulatory requirements, internal policies, and industry standards across multiple regions.

Yes. FlowForma’s AI agents can automate data extraction, validation, exception handling, and risk flagging. For example, they can flag low-margin trade promotions, incomplete supplier documentation, or non-conforming quality reports, enabling faster and more accurate decision-making.

By digitizing workflows, FlowForma connects cross-functional teams like Procurement, Quality, Marketing, Sales, Finance, and Regulatory. Automated notifications, task assignments, and approvals ensure stakeholders are aligned, deadlines are met, and bottlenecks are removed.

Absolutely. FlowForma can scale across multiple business units, regions, and product lines, handling high volumes of requests and approvals without slowing down operations. Its flexibility allows organizations to add new workflows as business needs evolve.

FlowForma automates inspection checklists, defect logging, corrective actions, and closure approvals. For product recalls, it ensures batch traceability, notifies distributors, tracks corrective actions, and generates audit-ready recall reports, helping FMCG companies maintain safety and compliance.

FlowForma provides real-time dashboards and detailed reporting for all workflows. Managers can monitor process performance, track bottlenecks, measure SLA adherence, and make data-driven decisions across supply chain, quality, and commercial operations.